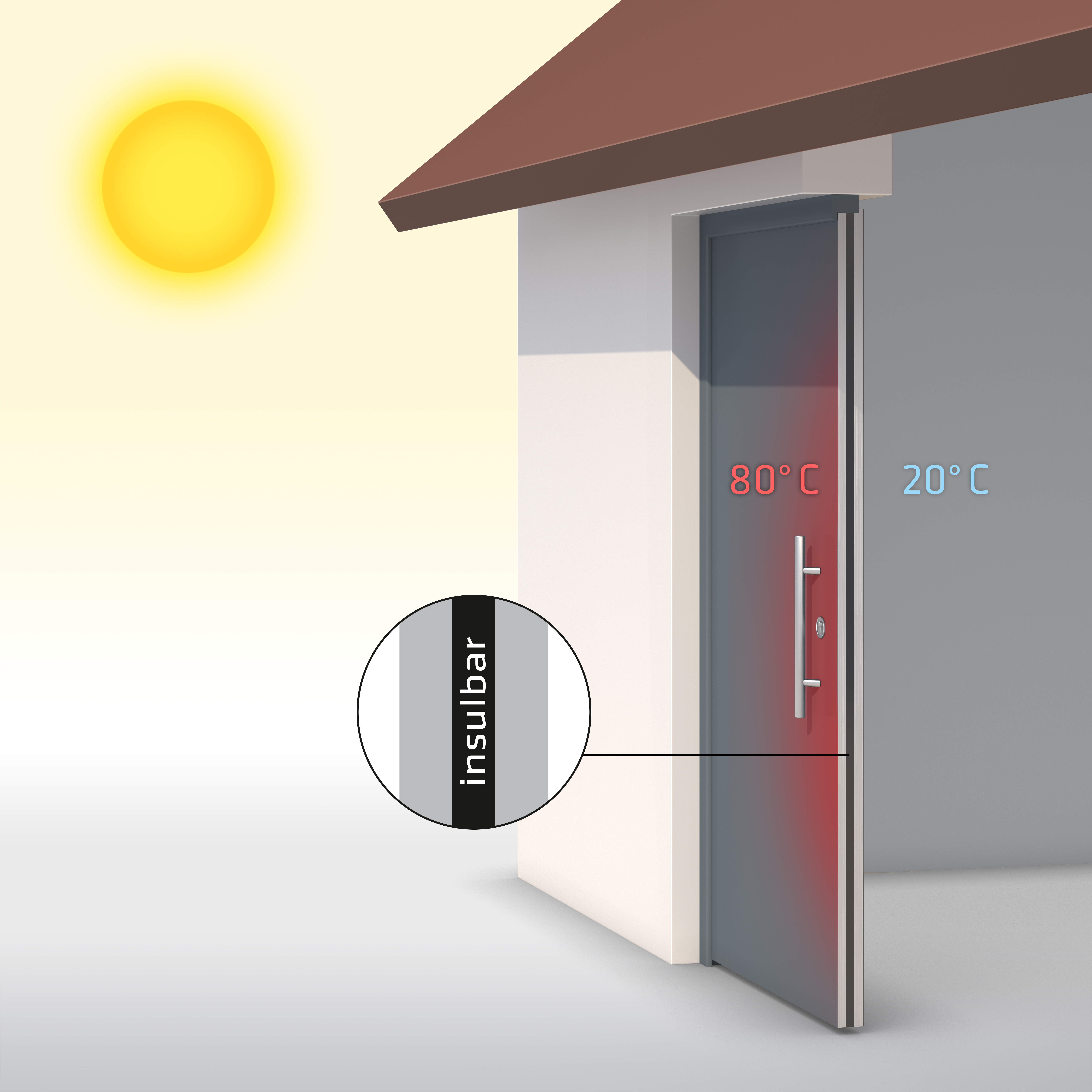

Minimising the bi-metal effect

The promise of a remedy for the ‘bi-metal effect’ comes in the form of the shear-free insulbar insulating profile, which Ensinger has developed specially for the thermal separation of metal doors and for which it has filed a patent.

At the gbd Lab testing institute in Dornbirn, Austria, front doors with anti-bi-metal profiles have now been put to the test. The institute compared a metal door with the shear-free insulbar bar and a door with the insulating profile with reduced elasticity constant from another manufacturer. With both test objects, the warping of the door in a longitudinal (B for bending) and transverse direction (C for curvature) was tested in different climates (reference climate, frost, heat) in accordance with testing standard EN 1121 and classified in accordance with EN 12219.

Flexible insulation zone

“Unlike shear-resistant profiles and profiles with a reduced elasticity constant, the shear-free polyamide bar from Ensinger consists of two parts which shift against one another when there is differing thermal expansion of the inner and outer shells of the door”, explains Matthias Rink, Sales Director for insulbar at Ensinger. “This generates a flexible insulation zone which still has a high transverse tensile strength that minimises the bi-temperature effect.”

The impact of the shear-free profile was confirmed during the test: With insulbar, the longitudinal warping of the 2.18 m x 1.23 m aluminium door was significantly less than 2 mm, and the transverse warping was less than 1 mm. Thus in all three climates tested, this door attains the best category B3/C3. The reference product only managed it into the category B2/C1 and was unable to fulfil the minimum requirement of the door manufacturer.

Summary: The warping of front doors that is the result of temperature-induced effects can be minimised effectively with the shear-free plastic insulating bar from Ensinger.

Further information: www.insulbar.com