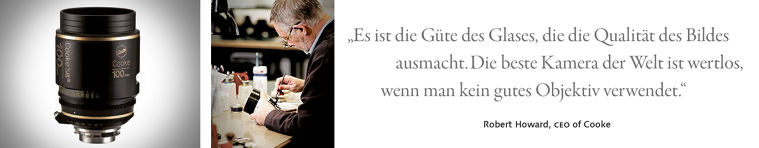

And Cooke was awarded the renowned ”2013 Academy Award of Merit (Oscar statuette)” for ongoing innovation in the areas of design, development and manufacturing. “The best camera in the world is really worthless if it doesn’t have a high-quality lens. And the quality of the glass is responsible for the quality of the picture,” explains Robert Howard, CEO of Cooke. ”We choose from hundreds of optical glasses and not just on the basis of refractive indexes, but also their color transmission properties. This enables us to control the various color frequencies that form a good picture,” he adds.

The company founded in 1894 manufactures up to twenty different molded lenses for each of its high-performance lens systems. Lenses that are made of either flint or crown glass are combined with various optical properties to obtain outstanding image sharpness and depth of color. Glasses with particularly low dispersion like N-FK51A and KZFS short flint glasses from SCHOTT with abnormal partial dispersion help correct aberrations.

The homogeneity of the glass and the precise determination of its properties are extremely important for users in the optics industry. SCHOTT achieves the narrowest tolerances by rigidly controlling the melting and annealing processes during manufacturing of optical glasses. For example, the deviation from the nominal values for the highest quality, as published in the data sheet, is only ±0.0001 for the refractive index and ±0.1 percent for the Abbe Number.

”We are intolerant when it comes to tolerances,” says Cooke. Manufacturing camera objectives is rather complex. ”Everything has to fit together perfectly. The system design, the quality of the optical glasses and the precision of grinding, polishing and refining,” explains Andreas Hädrich, Sales Director EMEA for SCHOTT Advanced Optics. ”We employ the latest state-of-the-art melting techniques and offer our long-time customer Cooke a broad range of high homogeneity optical glasses in the required specification. This enables us to manufacture lenses that deliver transitions from sharp to hazy areas that are as smooth as silk with brilliant color. This is simply ideal for creating unique cinema experiences,” he adds.

The ”Cooke Look” with its warm and natural colors is legendary in the film industry. ”With our innovations, we have been shaping the beauty of motion pictures from the moment they were born until today’s digital revolution,” emphasizes Les Zellan, Chairman, and owner of Cooke Optics. For example, the company developed the zoom lens for film cameras, light-sensitive lenses and, most recently, the revolutionary /i-Technology Protocol. It collects important metadata from the lens in order to provide the camera team and post-production crew with more accurate information.