“The characteristic property of the new product is its internal fine-pored, closed-cell structure. Thanks to these pores, the density of the material is reduced and the thermal conduction capacity of the insulating bar is therefore lower and hence particularly insulating”, explains Dr. Michael Möller, Head of insulbar Innovation Management. “Consequently it will primarily be used in special profiles where there are high demands on the insulating effect.”

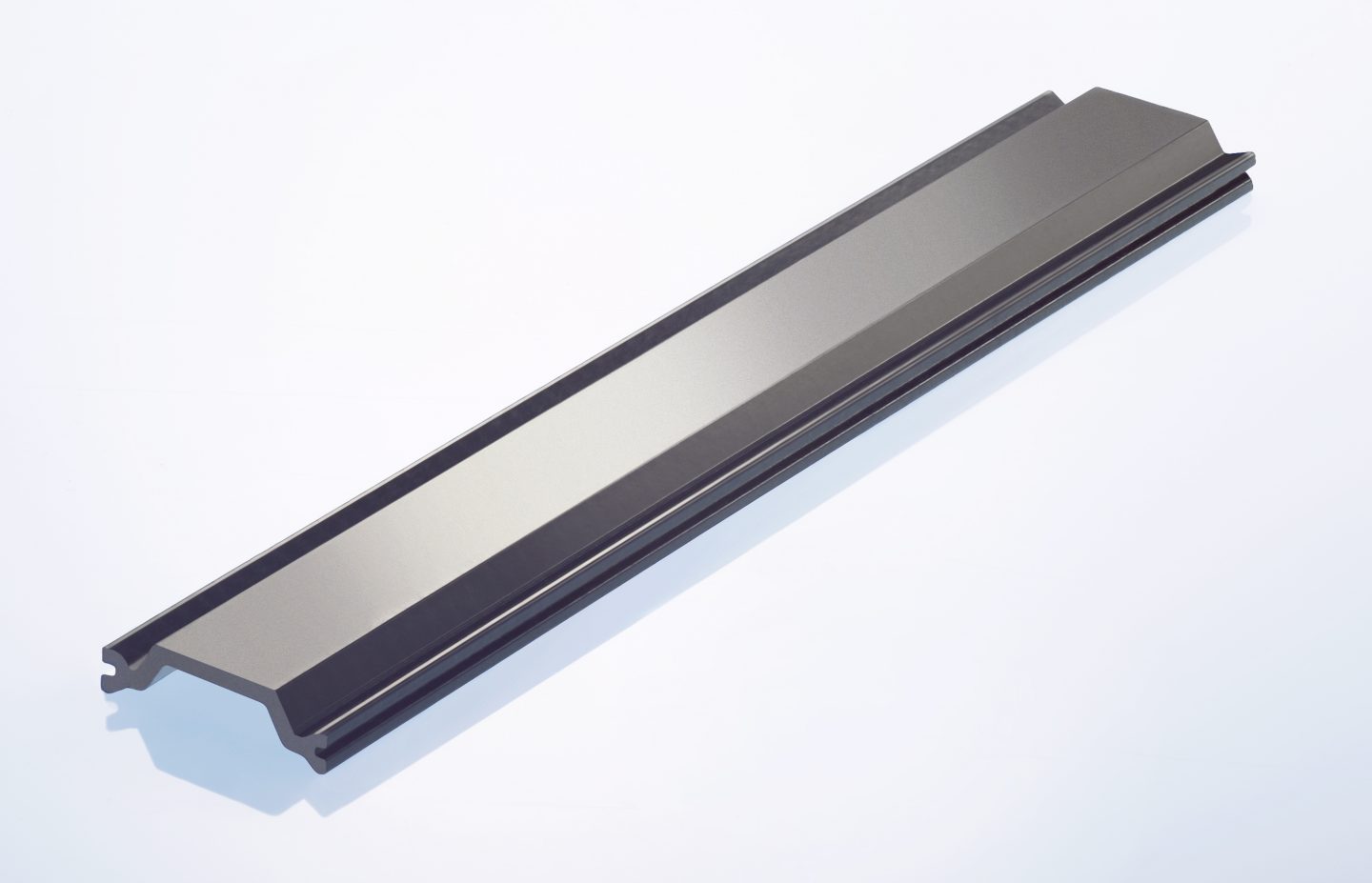

The porous insulbar insulating profile is produced from a new material and is currently undergoing suitability certification in line with DIN EN 14024. A special manufacturing process generates closed, scattered pores in the insulating bar; the product itself is based on the Ensinger Patent EP1242709 (B2). The surface of the profile remains compact and not porous.

Ensinger is among the leading developers and manufacturers of high thermally insulating profiles for window, door and façade construction. In 1977 the German company invented the world’s first plastic thermal insulting profile for thermally separated metal systems and in doing so revolutionised the market. Today, insulating bars from the plastic specialists are in successful use everywhere the world over, and they are being continuously further developed. Many innovations from Ensinger have been instrumental in shaping the thermal separation of metal windows, doors and façades.

For more information, go to: www.insulbar.de/en