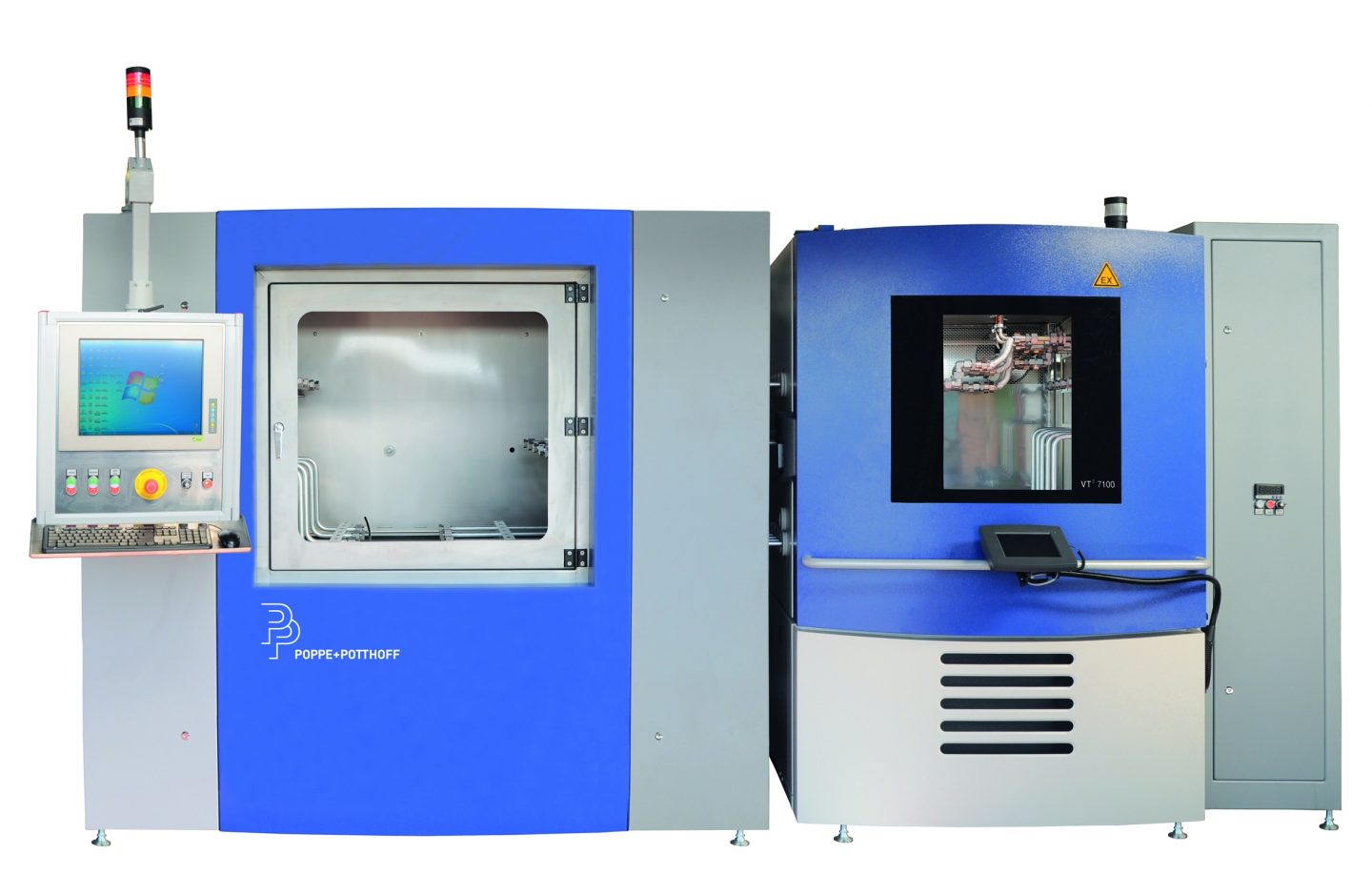

Equipped with climate chambers, the test stand exposes parts to temperatures from

-72°C to +180°C (-97.6°F to 356°F) and humidity up to 98%. The pressure adjustment ranges from -0.8 to +3.5 bar at a test frequency of 0.5 Hz and a test volume of 15 dm³ with various media (i.e. glycol, air, water, oil). This allows for pressure pulsation tests in the overpressure-overpressure, overpressure-vacuum and vacuum-vacuum range.

“Components in the automotive sector and many other industries are increasingly being made of special plastic”, says Johannes Montag, Head of Sales at Poppe + Potthoff Maschinenbau. “Our versatile test stand allows for applying various testing standards, for example for pumps, hoses, valves and the radiators for the cooling system of electric vehicles or novel air intakes for combustion engines”, he adds.

Three or more test connections are located on each side in the test chamber. They can be individually shut off via separate valves. An automated tightness test can detect leaks in any individual test piece every X cycles and exclude it from the test circuit. The measurement data acquisition, visualization, storage and data export is done with LabVIEW applications by National Instruments.

After presenting its capabilities at this year’s Automotive Testing Expo Europe (Stand 1104), the German expert for high pressure technology will also be attending the Automotive Testing Expos in China (booth 6048) and the USA (booth 1101). Its customized testing, autofrettage and automating machines are designed for precision and high-performance and are used worldwide in research, development and production.