Natural gas has become the world’s third most important energy carrier. Today, 30 percent of all gas is shipped in specially constructed seagoing vessels. In order to be able to load as much of it as possible, the gas is cooled down to minus 162 degrees Celsius. This process reduces its volume 600 fold. The Liquefied Natural Gas (LNG) is then pumped into the tanks on board the ship or into on-shore storage tanks or vaporizers that retransform it into gas.

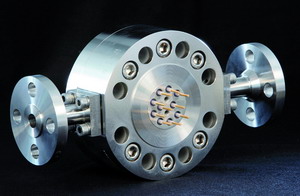

Modern tankers can carry up to 264,000 cubic meters of LNG inside their tanks. In order to unload the gas, each of the tank’s claddings contain three or four powerful electric pumps. Since they are completely immersed in liquefied gas, the pumps are protected against this harsh environment by a chassis. Terminal header assemblies serve as the hermetic feedthroughs for the three-phase electrical power, as well as the control and instrumentation conductors.

“Our glass-to-metal sealing technology has been setting the safety standard for power penetrations for almost three decades,” says Ulrich Dirr, Director of Sales for the Energy Safety Division of SCHOTT Electronic Packaging in Landshut. “We pursue the same goal with our plug-in control and instrumentation penetrations. In fact, we are the only supplier that offers a solution that has been certified according to the European ATEX directive and the international IECEx standard,” he adds.

SCHOTT subjects each feedthrough for LNG applications to one and a half times the maximum required design pressure and then examines it for hermeticity using helium mass spectrometers. Testing for electric strength and insulation guarantees reliable performance. While power penetrations are designed for voltages of up to 11,000 volts and current ratings of up to 1,000 amperes, the control and instrumentation (C&I) penetrations are designed for voltages of up to 28 volts and current ratings of up to 4 amperes.

While power penetrations can be delivered with individual dimensions, SCHOTT’s standard C&I penetrations are currently available with 10 pins for a 2 inch feedthrough or 16 pins for a 2.5 inch penetration. The unique design allows for the pins to be distributed across a wider distance. This helps to avoid cross-talk and interferences and ensures required clearance and creepage distances for explosion-proof components. After all, undisturbed transmission of motor speed counting and vibration detection signals are crucial to ensuring a long service life of the pumps.