“Ensinger is now the only supplier worldwide offering all materials for the manufacture of insulating bars from a single source: solid and foamed polyamide, foamed polymer blend, as well as recycled polyamide for further improved sustainability”, explains Matthias Rink, who is in charge of insulbar Sales at Ensinger.

Full-range supplier for improved thermal insulation

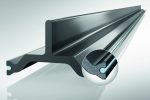

With the lower lambda value, the lower density of the profile means that the thermal separation of aluminium profiles – particularly in the middle insulating segment – can be noticeably improved. The insulating bar thereby permits a reduced installation depth while retaining the same Uf value, or alternatively an improved Uf value with the same installation depth.

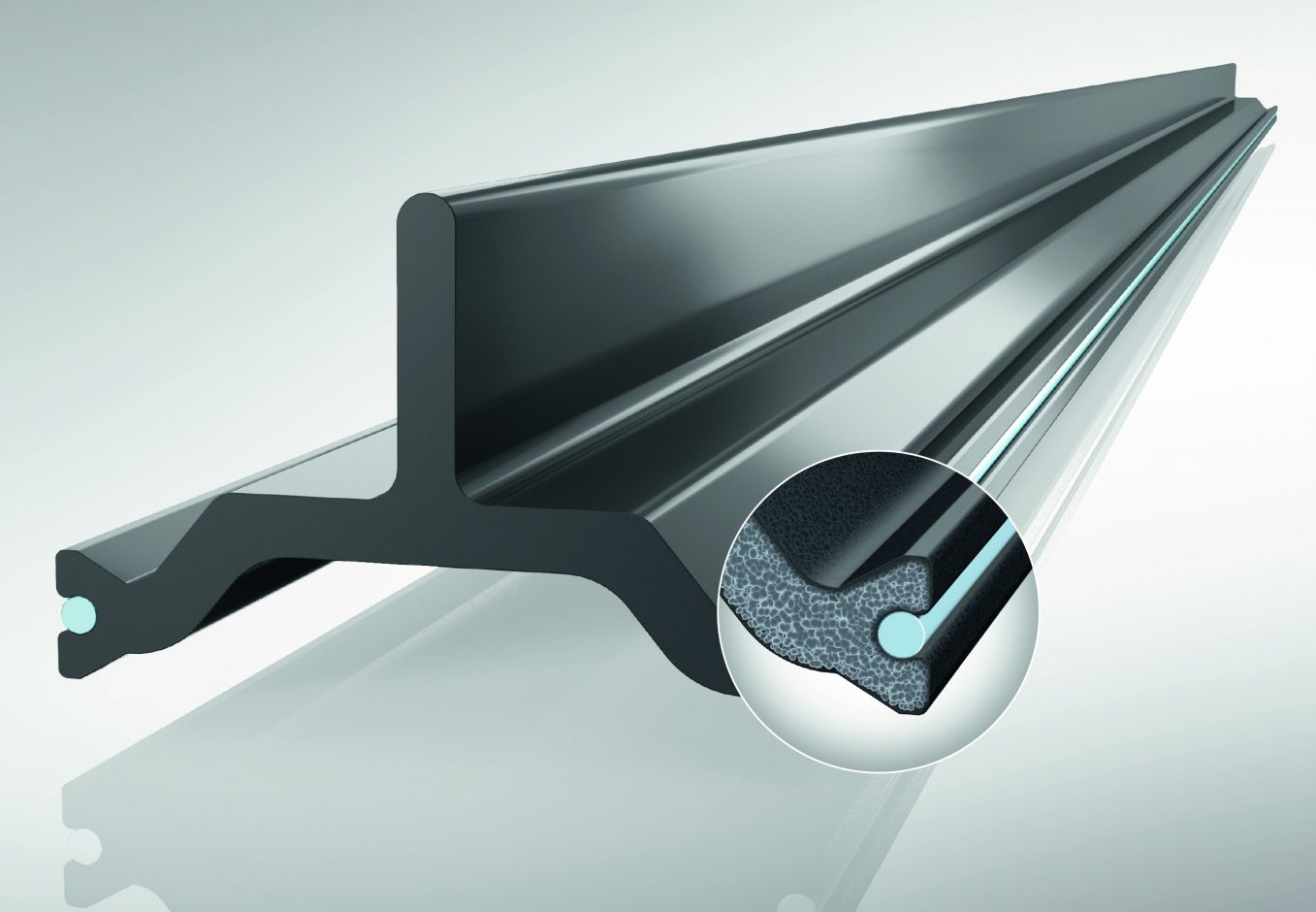

Thanks to a special production technique, the profile skin in insulbar LI bars from foamed PA remains unbroken. The visual appearance, quality and processing are comparable with the standard insulating profiles. They are produced with narrow tolerances, and a Coex wire can be incorporated on request.

Depending on the original system, a switch to insulbar LI makes it possible to reduce the Uf values by around 0.1 W/m2K. Existing window systems can therefore easily be thermally improved through a switch to insulbar LI and/or be offered in additional variants with different Uf values – without further system or process changes.

The right profile for every requirement

In the High Efficiency category at Ensinger, insulbar LO (lambda-optimised, 0.18 W/m⋅K), produced from a foamed polymer blend, and insulbar LEF from PA 66 with heat-reflective Low-E film, complement the portfolio. insulbar RE made from 100% recycled polyamide guarantees maximum sustainability. In addition, Ensinger offers flame-retardant, shear-free, highly rigid, electrostatically optimised and self-lubricating insulating bars for particular demands when it comes to application and processing.

All profiles satisfy the requirements of DIN EN 14024, are suitable for powder coating and for anodising and are impressive thanks to their high efficiency and long service life.