“Since 2003, SCHOTT has consistently been one of our top-performing suppliers,” says BAE Systems Maritime – Submarines Head of Supply Chain Category Management, Jeannette Medati. “The cross-functional, cross-business and multinational teamwork serves as a benchmark of what can be achieved by working together with joint aims, open and honest communication and a will to perform to the highest levels. We hope to continue in a spirit of true partnership for many years to come.”

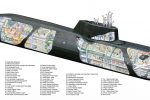

Contracted by the UK Ministry of Defence, BAE Systems is building the seven Astute class nuclear submarines for the Royal Navy. The performance and hermeticity of the electrical penetrations aboard the vessel are critical to safely running and controlling the boat’s reactor, which provides the submarine’s power. With its patent-registered compression glass-to-metal seals, SCHOTT offers a unique technology that maintains the pressure boundary integrity of the reactor’s containment structure in all conditions.

“Building a Space Shuttle is probably less complex than this nuclear submarine. Its more than one million components are engineered to serve for decades under the most demanding circumstances”, says Malcolm Bardsley, Sales Director UK at SCHOTT Electronic Packaging. “Technical expertise, on-time delivery and unfailing product performance are keys to such sophisticated projects. We are proud to contribute to the most capable submarine ever built for the Royal Navy.”

Since the early 1960’s, SCHOTT’s glass-to-metal sealed electrical penetration assemblies have been used in naval vessels ranging from civil icebreakers to aircraft carriers and LNG carriers as well as dozens of active nuclear power plants around the world. In rigorous testings – including seismic simulations and severe accident test programs beyond conditions believed to have occurred in 2011 in Fukushima – the robust components have proven their heat-, pressure- and radiation-resistant hermeticity and integrity.

“The pressure barriers of our penetrations basically consist of a metal housing, the sealing glass and the conductor pins. Pressure resistance and hermeticity are achieved by compression of the glass due to the considerably higher coefficients of thermal expansion of the housing material”, explains Dr. Oliver Fritz, Head of Technology at the Nuclear Safety Division of SCHOTT Electronic Packaging. “Unlike polymer seals, glass is inorganic and therefore non-aging. Offering a virtually unlimited lifetime for their pressure barriers, the penetrators remain functional and hermetic far beyond the ship’s service life of 25 years with no need for maintenance or replacement.”Additional information: www.schott.com/epackaging