The muntin bars are available to match the Thermix® TX.N® plus spacers in six colours, and on request individual colour requests can be implemented (see “Muntin bars for Leipzig Opera House“). Supplementary accessories such as cruciforms and end pins ensure secure connections. Configured as rectangular hollow chamber profiles, Thermix® muntin bars are far easier to process than duplex solutions using spacer profiles. Thermix® muntin bars are manufactured from glass fibre-reinforced plastic. The materials are UV-resistant and free of fogging, and the polymer used has impressively low thermal conductivity.

Muntin bar: Superb appearance and energy credentials

But how does the bar generally affect the window’s thermal transmission coefficients? First of all, an important distinction must be made: Is the window fitted with a structural bar, a decorative bar or a muntin bar? A “real” or structural bar used to join several insulating glass units to form a single window is the most inefficient in thermal technology terms. Decorative bars and muntin bars are significantly better here. They are mounted in the space between panes and only appear to divide the insulating glass. Unlike the use of internal decorative bars, when using muntin bars the window producer additionally mounts ornamental strips on the outside of the glass. These make the window appear like a real glazing bar window (see info box “The bar makes all the difference”).

In accordance with DIN EN 14351-1, table J.1, the Uw value is calculated by adding a flat-rate value to the Uw value of a window without bars. In practice, however, this method is actually highly imprecise and shows the bar in a detrimental light, as the added value is based on a “worst-case scenario”. When performing a precise calculation, the opposite is shown to be the case: If a “warm” system is used made of engineering plastic, such as the Thermix® muntin bar, the increase in the Uw value is only in the hundredths.

Precise calculation of the Uw value with bar

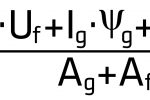

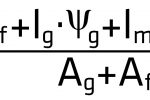

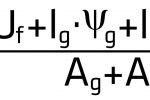

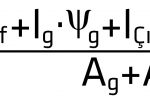

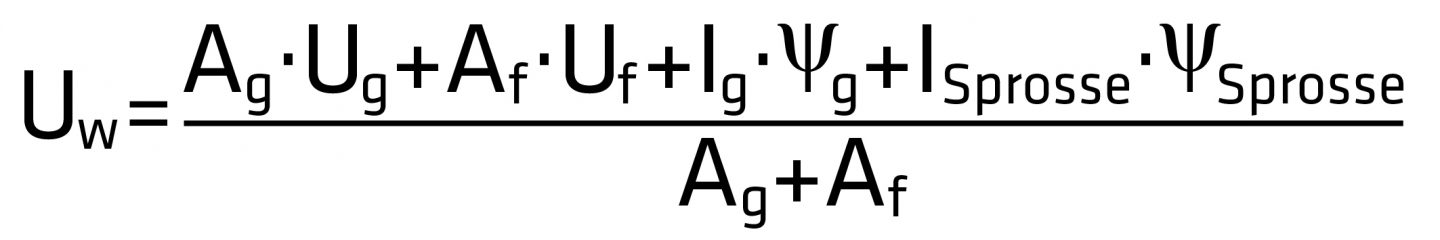

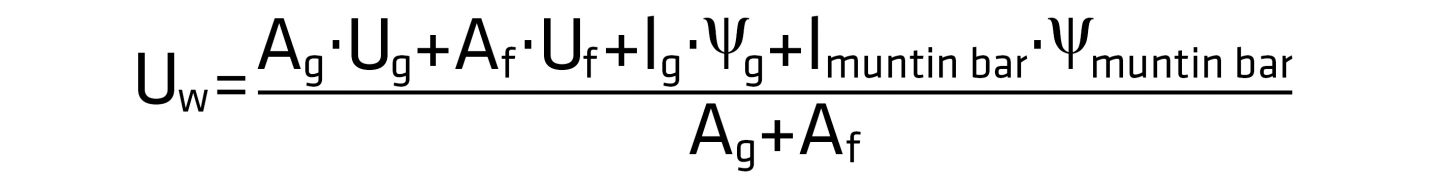

To calculate the thermal transmission coefficient (Uw) of a glazing bar window, in addition to the known variables only the length and the Ψ value (in other words: Psi value) of the bar are required. The calculation formula is as follows:

Underlying Ψ values for the Thermix® muntin bar have been calculated by the Window Technology Institute ift Rosenheim for double and triple-glazed units, and are shown in the Ensinger data sheet. Ensinger will be pleased to calculate the Ψ values for different insulating glass constructions made with Thermix® muntin bars on request.

To facilitate the calculation of thermal transmission coefficients for architects, planners and window producers, from middle of September, Ensinger will be providing an updated, easy-to-use Uw calculator on its website www.thermix.de/en which will provide fast, accurate results. Other online helps from Ensinger include a window configurator and a heating cost calculator, which demonstrates with just a few clicks how effective thermally optimized windows can be in reducing heating costs for households.

The bar makes all the difference:

Glazing bar windows can be classified in three common underlying types:

- Structural bars: In this case, the window is actually made up of individual small insulating glazed units. This has a negative impact on the thermal characteristics of the window, as the edge bond accounts for a higher proportion of the overall glass surface. This is the reason why this type of window is assigned the highest flat-rate increase in the thermal transmission coefficient with ΔUW = 0.4 W/(m2K) in accordance with DIN EN 14351-1. In addition, the edge bond is subject to higher loads when using small-format glass panes.

- Decorative bars: Decorative bars are positioned between the insulating glass panes and no other bars or strips are mounted outside on the insulating glass. This means that a flat glass surface is retained, the visual impression is not the same as for a window with structural bars.

- Muntin bars: The muntin bar lends the glass the optical impression of a structurally divided window. The bar is located between the insulating glass panes. On the outside, decorative strips are stuck onto the pane. The flat-rate values added in accordance with DIN EN 14351-1 for decorative and muntin bars are identical. They are ΔUW = 0.1 W/(m2K) for a single cruciform and ΔUW = 0.2 W/(m2K) for a multiple cruciform. If instead of taking the rough approximation value, the Ψ value of a thermally optimized Thermix® muntin bar is used, it becomes evident that the thermal transmission coefficient increases in most cases by just a few hundredths.

Sample calculation with a Thermix® muntin bar:

Thermix® muntin bars are made of engineering plastic, whose thermal conductivity is around 700 times lower than aluminium. This not only allows savings to be made in terms of heating costs, but also substantially reduces the risk of condensation and mould formation in the glass edge area of the bars due to increased surface temperatures.

What is the Uw value of a wooden window in a standard size of 1.23 x 1.48 m with a Uf value of 1.4 W/(m2K) and thermal insulating glass (4/16/4) mm with Ug=1.1 W/(m2K), with a single cruciform and 21.4 x 11.4 mm Thermix® muntin bar?

- If the flat-rate increase as specified by DIN EN 14351-1 is applied, a Uw value of 1.4 W/(m2K)

- When calculating on the basis of Ψ values, the Uw value increases only by 0.02 W/(m2K) to 1.32 W/(m2K). As only two value-indicating points are specified, the Uw value would still be 1.3 W/(m2K).

In a single family home with appr. 30 m2 of window surfaces, the bar would result in a theoretically increased heating cost of just around 4 € per year.